INCOMING INSPECTION

Three Coordinates Testing Equipment

Carburetor Flow Meter

Hardness Tester

Salt Spray Tester

Flywheel Balance Test Bench

deflection instrument

Oil pump Test Bench

Surface Test Instrument

Tension Test Bench

Pneumatic Measuring Instrument

Microscope measuring instrument

Metallographic Inlaid Instrument

PRODUCTION WORKSHOP

Engine Workshop

Engine Workshop

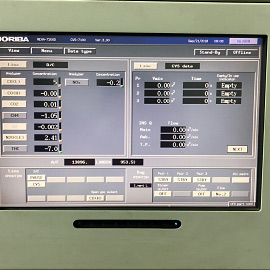

On-line Debugging Equipment and Flow Meter

On-line Debugging Equipment and Flow Meter

On-line Debugging Equipment and Flow Meter

On-line Debugging Equipment and Flow Meter

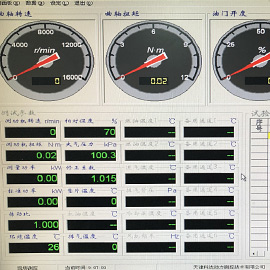

Full Inspection Line for Emission

Full Inspection Line for Emission

ORDER TRACKING

Tracking System

Tracking System

Tracking System